More accidents mean higher Truck Insurance, so it's crucial that all truck drivers understand potential hazards and how to avoid them. One hazard common to all drivers is deer and other animals. According to the Insurance Institute for Highway Safety, there was an upward trend in deaths from collisions with animals from 1975 to the mid-2000s, which has leveled off in the past few years.

More accidents mean higher Truck Insurance, so it's crucial that all truck drivers understand potential hazards and how to avoid them. One hazard common to all drivers is deer and other animals. According to the Insurance Institute for Highway Safety, there was an upward trend in deaths from collisions with animals from 1975 to the mid-2000s, which has leveled off in the past few years.

In 2020 there were 202 deaths from collisions with animals, reaching costs as high as $1 billion annually in damages nationwide. While smaller vehicles often experience more damage when colliding with large animals, commercial trucks are not immune. Collisions with animals can result in injuries or death, damage to trucks and cargo, lost time, and loss of revenue.

Sometimes collisions with deer and other animals are unavoidable, but there are steps truck drivers can take to minimize the risk and the damage caused by these collisions.

Know where there is higher risk.

Deer sightings can occur just about anywhere, but there are certain areas and times that have a higher risk.

- According to the Insurance Information Institute, the top five states in 2021-2022 for the likelihood of animal-involved claims from a collision are West Virginia (1 in 35), Montana (1 in 44), South Dakota (1 in 51), Michigan (1 in 51, Wisconsin (1 in 54), and Pennsylvania (1 in 57). Therefore, drivers in these states should be more vigilant.

- Watch for the yellow, diamond-shaped signs with an image of a deer, which indicates an area of high-level deer activity. When you see one of these signs, you should be extra alert.

- According to the Pennsylvania Game Commission, deer are most active during the dusk to dawn hours.

- Autumn (November – the peak, October, and December) are a deer's breeding season, and they may be less aware of their surroundings.

- In May and June, one-year-old deer begin to disperse to new areas.

- Less populated states and regions tend to have higher animal populations.

- Long stretches of isolated highways tend to have a higher risk of an animal darting in front of a truck.

- Rural highways built along creeks, rivers, and lakes attract deer.

- Heavily forested areas have higher animal populations.

- Areas where farmers are harvesting crops, can cause deer to run onto a road.

- During hunting season, deer are more likely to bolt in front of an oncoming vehicle.

- If you travel a route regularly, watch for a pattern of areas with higher activity of deer and other animals.

- Deer tend to travel in packs, so if you see one deer, chances are there are more nearby, and you need to remain on high alert.

Drive Safely

- Stay alert.

- Continually scan the road for signs of animals and activities.

- Use high beams when there is no oncoming traffic. Light can reflect off an animal's eyes, revealing its location.

- Always wear your seat belt.

- Eliminate distractions.

- Drive the posted speed limit.

- Never drive impaired.

- If driving on a multi-lane road, stay in the center lane to give you more time to respond if a deer runs onto the road.

- Don't tailgate. Allowing space between you and the vehicle in front of you provides a broader field of vision and more reaction time, enabling you to break rather than swerve if a deer runs in front of you or the vehicle in front of you.

Know what to do if a deer does come into your path.

If a deer or other animal crosses your path, try to stay in your lane and avoid the urge to swerve. Swerving can cause you to lose control and increase the chance of colliding with another vehicle or ending up in a ditch. Plus, deer can be unpredictable, and swerving may put the deer right in your path. It's better to hit the deer than risk veering off the road, overturning your truck, or hitting another vehicle.

Sometimes, using your horn can frighten the animal and keep them off the road.

If a collision is imminent, remove your foot from the brake because braking hard may cause the front end of your vehicle to go down, causing the animal to fly over your hood and towards your windshield.

How to Save on Truck Insurance

At American Insuring Group, we go beyond providing you with affordable truck insurance. First, we carefully analyze the needs and risks associated with your business. Then, we match you up with the best trucking insurance policy based on a careful analysis of many competing insurance companies. The result? You get the high-quality commercial insurance coverage you need at a very affordable price.

Get a free quote today by calling (800) 947-1270 or (610) 775-3848, or connect with us online.

Injuries within your restaurant can significantly increase the cost of

Injuries within your restaurant can significantly increase the cost of  The key to lowering

The key to lowering

To keep

To keep  Finding and retaining good employees is often cited as one of the biggest challenges employers face, and the current labor shortage isn't making it any easier. Hiring new employees can be time-consuming, frustrating, and costly. According to

Finding and retaining good employees is often cited as one of the biggest challenges employers face, and the current labor shortage isn't making it any easier. Hiring new employees can be time-consuming, frustrating, and costly. According to  Construction sites are filled with hazards/risks that cause injuries and fatalities, increasing both direct and indirect costs, such as lost workdays, lower employee morale, and higher

Construction sites are filled with hazards/risks that cause injuries and fatalities, increasing both direct and indirect costs, such as lost workdays, lower employee morale, and higher  Ask any good insurance agent how to lower

Ask any good insurance agent how to lower  The COVID-19 pandemic reminded restaurant owners and managers of the importance of proper sanitation - whether they’re running a food truck or a fine dining restaurant. So perhaps it’s a good idea to continue some of those additional precautions even as the mandates are lifted.

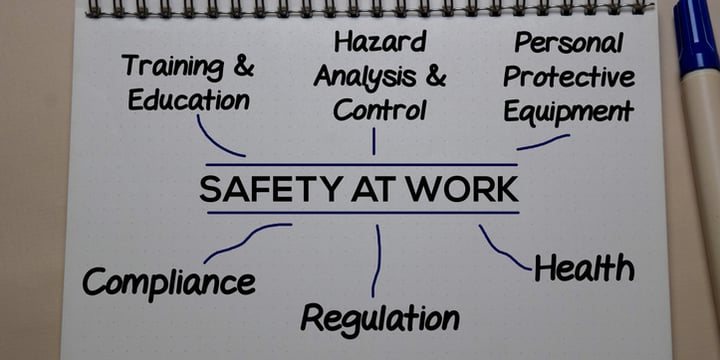

The COVID-19 pandemic reminded restaurant owners and managers of the importance of proper sanitation - whether they’re running a food truck or a fine dining restaurant. So perhaps it’s a good idea to continue some of those additional precautions even as the mandates are lifted. Minimizing injuries in the workplace benefits everyone – from a better quality of life for employees to higher productivity and lower

Minimizing injuries in the workplace benefits everyone – from a better quality of life for employees to higher productivity and lower